How to quickly select a high-quality adhesive interlining

2023-02-06.

At present, in most clothing, adhesive interlining has gradually replaced the traditional wool, linen, cotton and other interlinings, becoming the main lining of clothing. The application of adhesive interlining has changed the traditional sewing concept, and with the birth of a new system of sewing technology adapted to it. High-quality adhesive interlining fabrics can make clothing have the advantages of light, thin, soft, straight, easy to wash, good modeling performance, and also have the advantages of easy use and simplified process. Due to the wide use of adhesive interlinings, mastering the use of adhesive interlinings in clothing technology plays a key role in the quality of clothing.

Selection of adhesive interlinings

1. Adhesive interlining can be divided into two categories: woven adhesive interlining (commonly known as spun lining) and non-woven adhesive interlining (commonly known as non-woven lining), which is made of evenly coated with a layer of hot melt resin glue by special equipment on the base step of weaving and nonwoven. The hot melt adhesive attached to the base step can be divided into several types such as dot, strip, powder, sheet, network and film according to its different surface shapes. Weaving adhesive interlining can be divided into two types: woven and knitted, and the thickness of the weaving adhesive interlining is mainly determined by the yarn support of the base fabric. Generally, the coarse weaving adhesive interlining is the thickest, followed by the middle branch and high branch.

2. In addition to the base fabric of the bonding interlining, the thickness of the bonding interlining is also related to the surface morphology of the hot melt adhesive. Generally, the same base fabric, the dotted adhesive interlining is the thickest, followed by strips, powders, sheets, and nets. The weaving adhesive interlining has good washability, heat resistance and shape retention performance, but the cost is high, and it is generally bonded with an adhesive machine when conditions permit. Nonwoven bonded interlining fabric has low melting point, fast bonding, low cost, and no warp and weft direction, so it is easy to use.

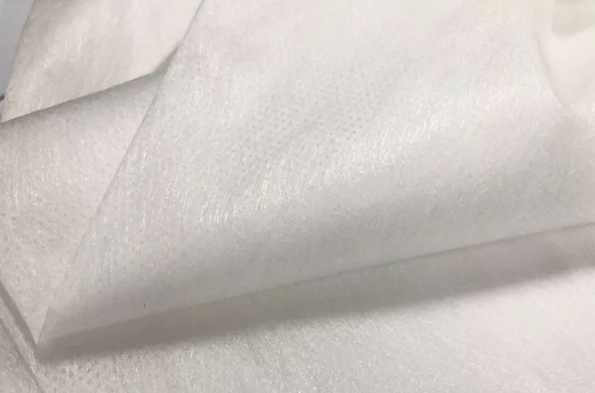

Hot rolled non-woven interlining

Peculiarity

It can be firmly bonded with the fabric, and the cloth surface is flat after bonding, no wrinkles, no foam, no glue; It feels soft and structured, elastic, and the surface of the fabric creases quickly after bonding. Peeling, dry cleaning and washing performance tests have reached national standards and European standards.

Scope of application

Wool, silk, collars of knitted fabrics, top fronts and coats (full clips), summer men's and women's clothing, children's clothing, coat predecessors, toddlers, men's and women's outerwear, suits and coats precursors and toggles.