How to use fusible interfacing

2023-03-13.

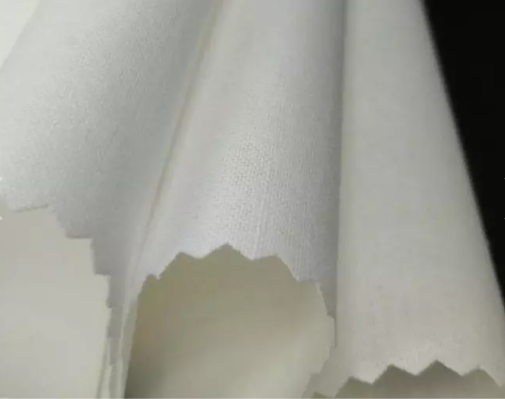

Fusible interfacing is a type of interlining that is designed to be bonded to the fabric using heat and pressure. It is commonly used in garment making to add structure, stability, and support to areas such as collars, cuffs, and waistbands. Here are the steps to using fusible interfacing:

Choose the right fusible interfacing: Fusible interfacing comes in different weights and stiffness levels, so it's important to choose the right type for your project. Look for the weight and stiffness level recommended for your fabric and project.

Cut your interfacing: Cut your interfacing to the size and shape needed for your garment piece. It's best to cut the interfacing slightly smaller than the fabric piece to avoid any excess bulk.

Place the interfacing on the wrong side of the fabric: Place the fusible side of the interfacing facing down onto the wrong side of the fabric. Make sure the interfacing is centered and aligned with the fabric.

Apply heat and pressure: Use a dry iron on the appropriate heat setting for your fabric to press the interfacing onto the fabric. Hold the iron in place for 10-15 seconds, applying pressure evenly across the entire piece of interfacing. Repeat until the entire piece of interfacing is bonded to the fabric.

Allow to cool: Once the interfacing is bonded to the fabric, allow it to cool completely before handling or sewing. This will ensure that the bond is strong and secure.

Trim excess interfacing: After the interfacing has cooled, trim any excess interfacing from the edges of the fabric piece. This will help to reduce bulk and make your seams easier to sew.

Overall, using fusible interfacing is a simple process that can greatly enhance the structure and stability of your garments. With the right type of interfacing and proper application technique, you can achieve professional-looking results in your garment-making projects.