Interlining in Garment Manufacturing

2023-03-29.

Interlining is a layer of fabric that is inserted between the outer fabric and the lining of a garment to add structure, shape, and stability. It is commonly used in the manufacturing of tailored garments, such as suits, blazers, and coats, to give them a crisp, professional appearance.

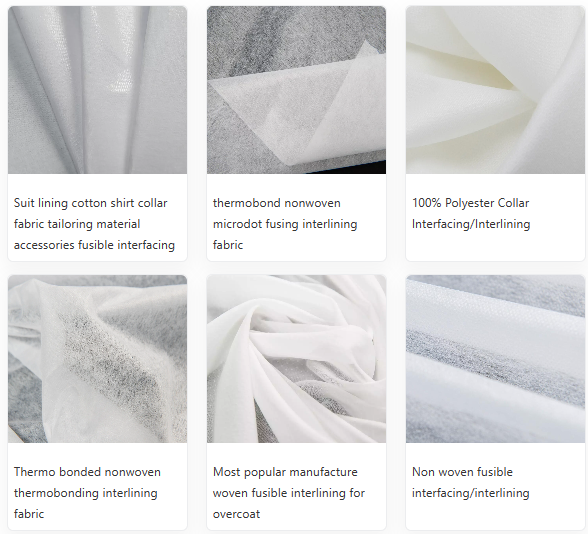

Interlining can be made from a variety of materials, including cotton, wool, silk, polyester, and fusible interfacing. Fusible interfacing is a popular choice as it can be bonded to the fabric using heat and pressure, making it easier to work with and giving a cleaner finish.

The process of interlining involves cutting the interlining material to the same shape as the outer fabric pieces, and then attaching them together using a variety of techniques, such as basting, fusing, or sewing. The interlining is then stitched into the garment along with the outer fabric, and the lining is added on top to cover the interlining and give the garment a finished look.

Interlining is an important part of garment manufacturing as it provides structure and support to the garment, helping it to maintain its shape and drape properly. It also adds durability to the garment, making it last longer and look better over time. Without interlining, tailored garments may look limp and shapeless, and may not hold up well to wear and tear.